Galvanized seamless pipe round tube

Hot-dip galvanized steel pipe is a type of corrosion-resistant steel pipe formed by immersing steel pipes in molten zinc to create a zinc coating, featuring excellent corrosion resistance and mechanical strength. Its core advantage lies in the formation of an alloy layer between the zinc coating and the steel pipe substrate, significantly extending its service life. It is widely used in construction, energy, transportation, and other fields.

Description

Selection of Zinc Coating

Product Application

Galvanized steel pipes are versatile and durable, widely used in construction, furniture, agriculture, and industrial projects. Perfect for both structural and decorative applications.

Competitive Advantages

High Quality Raw Material

Manufactured from carefully selected carbon steel slabs, ensuring stable chemical composition and mechanical performance suitable for various industrial applications.

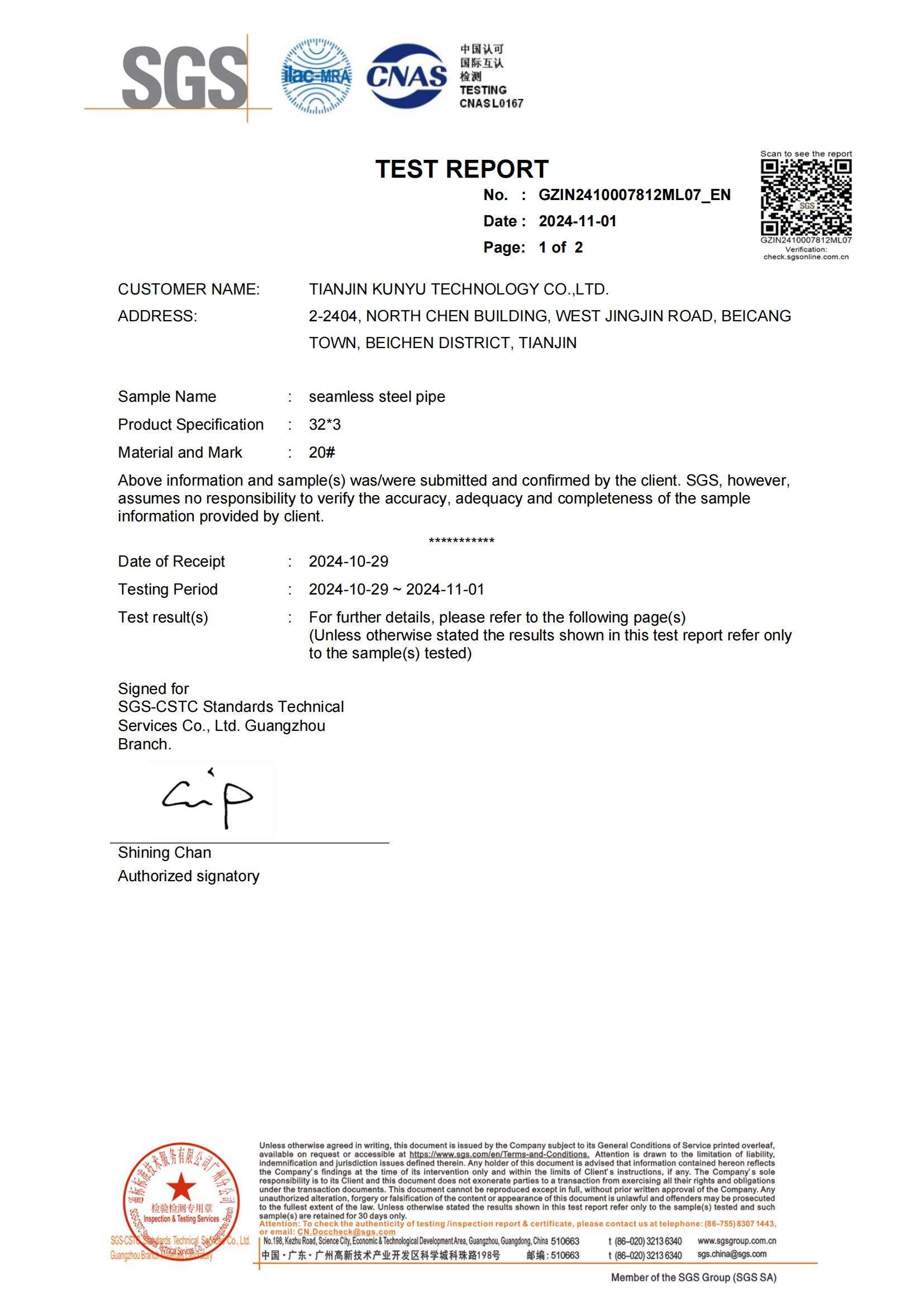

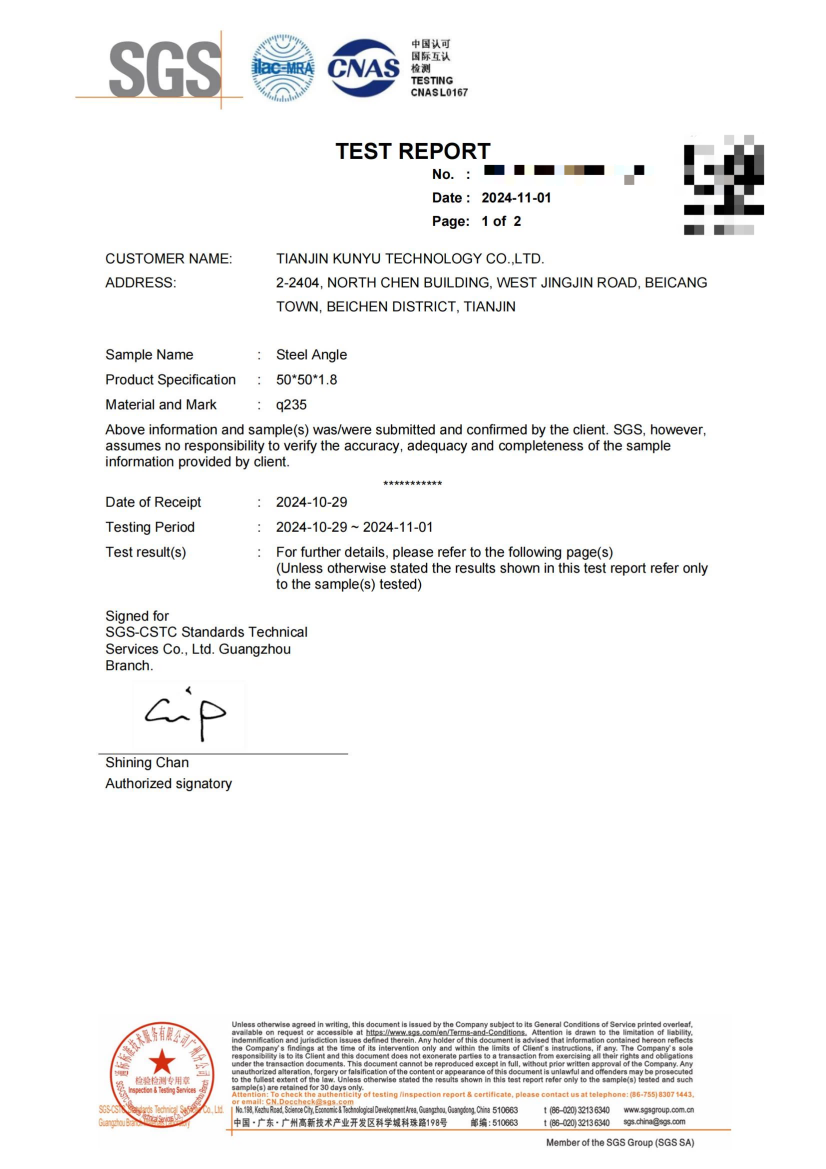

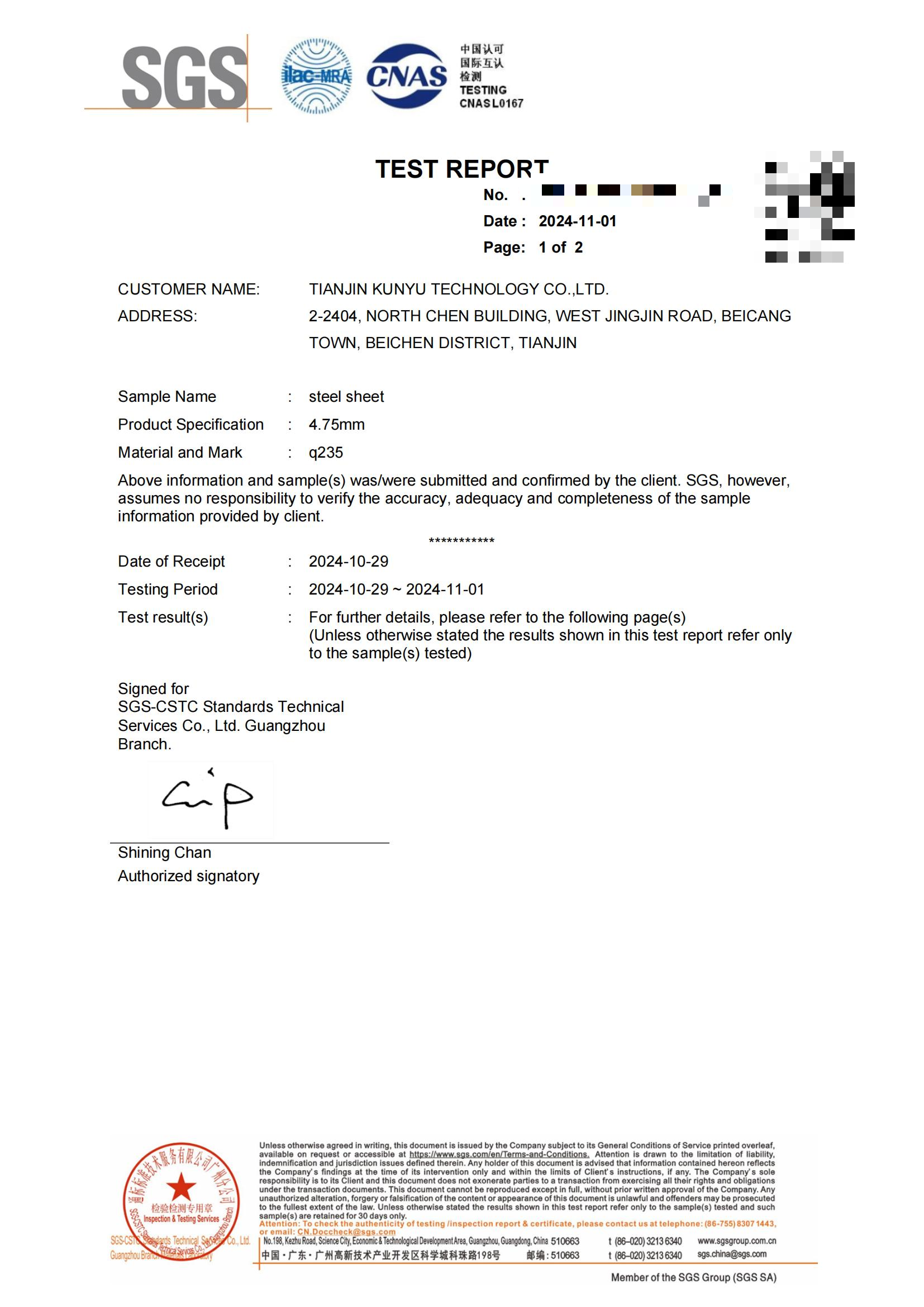

Strict Quality Control

Each batch undergoes inspection including chemical analysis, tensile testing, and dimensional verification before shipment.

Wide Specification Range

Available in a broad range of thicknesses and widths to meet different project and processing requirements.

Excellent Weldability

Optimized carbon content ensures good weldability and processing performance during fabrication.

Manufacturing Process

1. Steel Billet Preparation

High-quality carbon steel or alloy steel billets are selected in accordance with applicable standards. The chemical composition, internal soundness, and dimensions of the billets are inspected to ensure suitability for seamless pipe production.

2. Heating

The steel billets are heated uniformly in a heating furnace to the required temperature for piercing and rolling. Proper heating ensures good plasticity of the steel and stable forming during subsequent processes.

3. Piercing

The heated billets are pierced by a piercing mill to form hollow shells. This is a critical step in seamless steel pipe manufacturing and has a direct impact on the internal quality of the pipe.

4. Rolling and Sizing

The hollow shells are rolled through a series of rolling mills to achieve the required outer diameter and wall thickness. Sizing or reducing processes are applied to ensure dimensional accuracy and uniform wall thickness.

5. Cooling and Straightening

After rolling, the seamless pipes are cooled and straightened to eliminate bending and deformation, ensuring proper straightness and surface appearance.

6. Surface Preparation (Pre-Galvanizing Treatment)

Before galvanizing, the seamless pipes undergo degreasing, pickling, and fluxing to remove surface contaminants and oxides. This process ensures excellent adhesion between the zinc coating and the steel substrate.

7. Hot Dip Galvanizing

The prepared pipes are fully immersed in molten zinc. Through metallurgical reactions between zinc and steel, a uniform, dense, and strongly bonded zinc coating is formed on both the internal and external surfaces of the pipes, providing superior corrosion protection.

8. Cooling, Passivation and Inspection

After galvanizing, the pipes are cooled and passivated to reduce the risk of white rust during storage and transportation. Comprehensive inspections are then carried out, including dimensional checks, zinc coating thickness measurement, and surface quality inspection.

9. Cutting, Marking and Packaging

The galvanized seamless pipes are cut to required lengths, marked according to customer or standard requirements, and securely bundled and packaged for shipment.