Description

Product Name |

Galvanized steel wire |

Grade |

SAE1006-1080,WA1010,Q195,SWRH32-37,SWRH42A-77A,SWRH42B-82B |

Standard |

GB standard,ASTM standard |

Wire Gauge |

5.5mm-34mm |

Dia tolerance |

+/-0.3mm |

Process |

Hot rolled |

Application |

Mechanical&manufacture,Steel structure,Shipbuilding,Bridging,Automobile chassis |

Lead Time |

A.7 days if this goods is stock goods.B.20 days if this goods will be produced after order |

Product Business Terms

|

Minimum Order Quantity: |

1 ton |

|

Price: |

420-550/ton |

|

Packing |

Seaworthy Standard Package |

|

Delivery Time: |

15-21days |

|

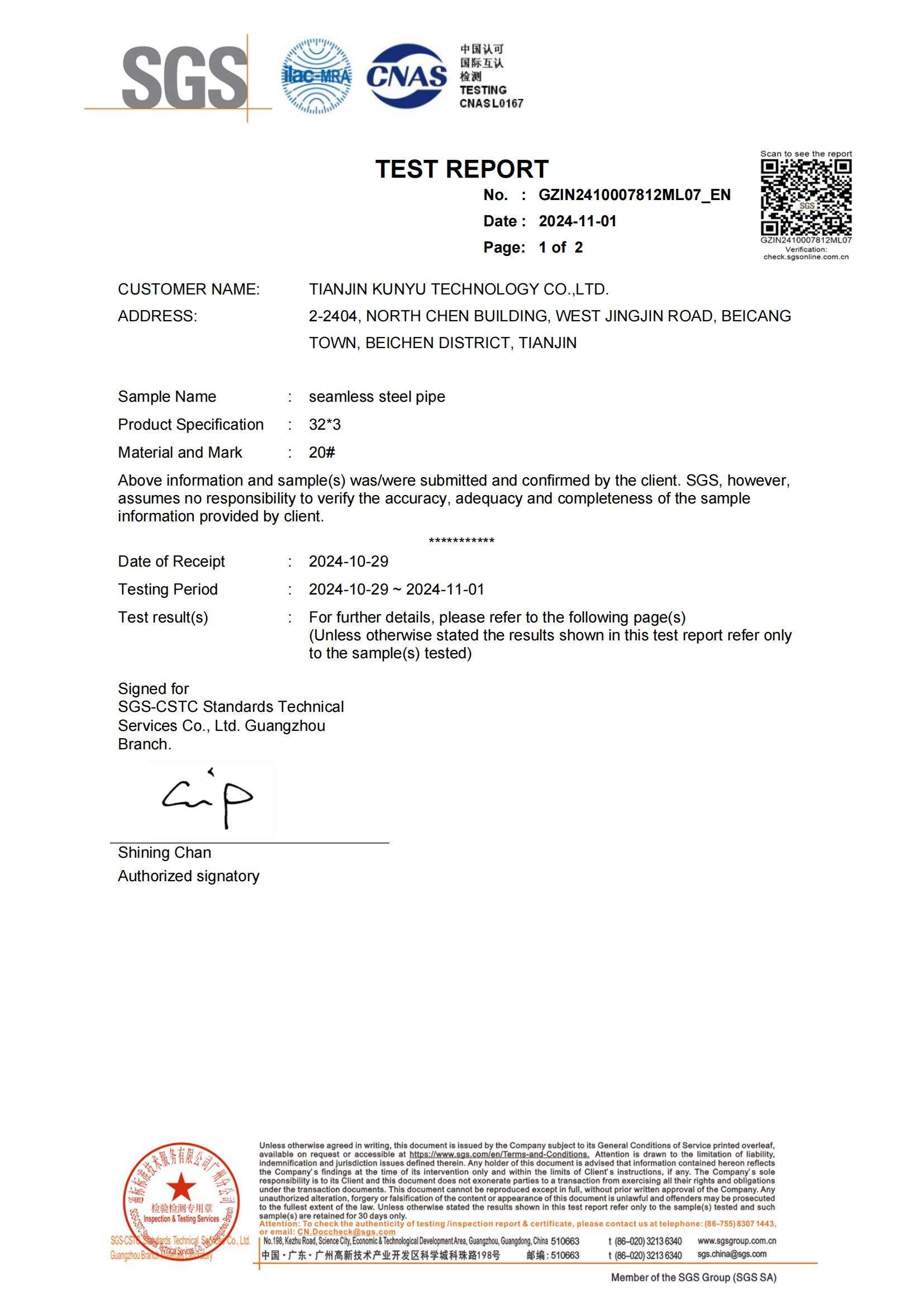

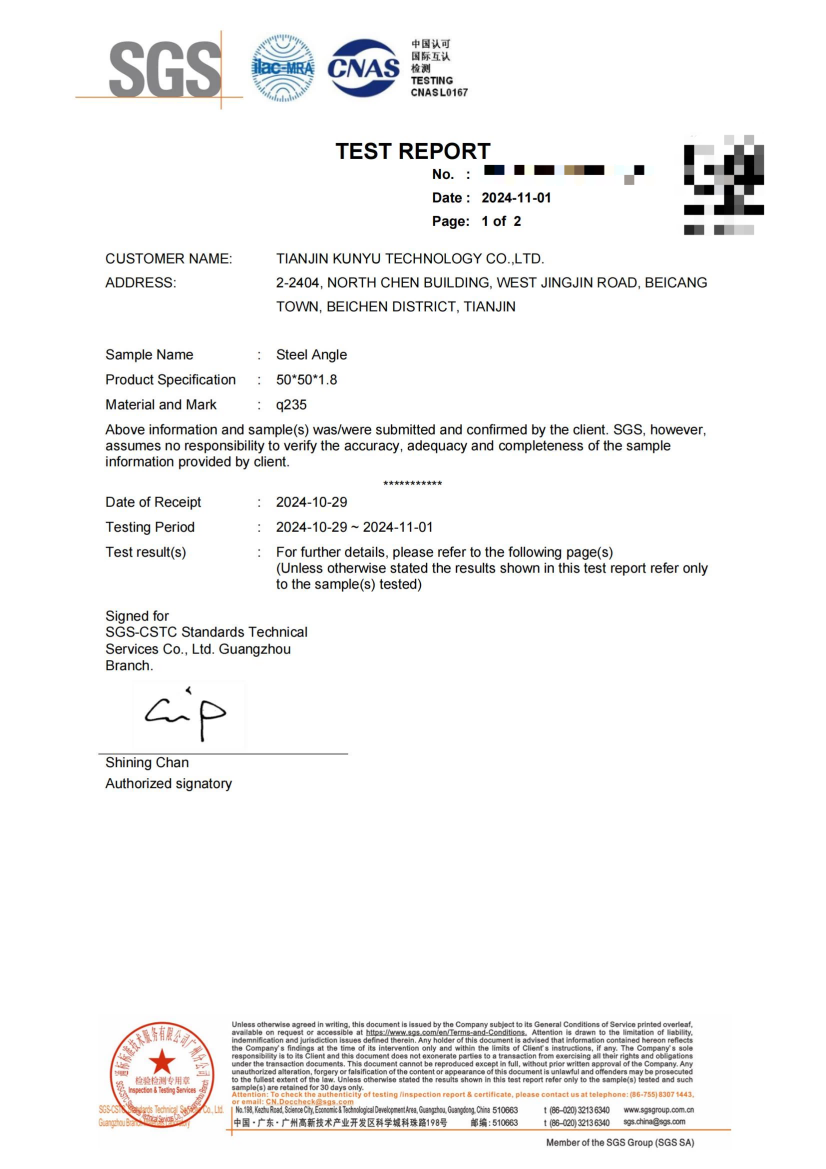

Certificate |

ISO9001,CE |

Product presentation

Galvanized steel wire features a smooth and clean surface, free from cracks, joints, burrs, scratches, and rust. With outstanding anti-corrosion properties and an extended service life, it is suitable for engineering structures in harsh environments, such as bridge cables for cable-stayed bridges and wastewater treatment tanks. It can also be used for greenhouse construction, livestock farms, cotton baling, and the manufacturing of springs and steel wire ropes.

Product specification

Common wire diameter

|

Model |

SWG in mm |

BWG in mm |

metric system mm |

|

8# |

4.06 |

4.19 |

4.00 |

|

9# |

3.66 |

3.76 |

- |

|

10# |

3.25 |

3.40 |

3.50 |

|

11# |

2.95 |

3.05 |

3.00 |

|

12# |

2.64 |

2.77 |

2.80 |

|

13# |

2.34 |

2.41 |

2.50 |

|

14# |

2.03 |

2.11 |

- |

|

15# |

1.83 |

1.83 |

1.80 |

|

16# |

1.63 |

1.65 |

1.65 |

|

17# |

1.42 |

1.47 |

1.40 |

|

18# |

1.22 |

1.25 |

1.20 |

|

19# |

1.02 |

1.07 |

1.00 |

|

20# |

0.91 |

0.89 |

0.90 |

|

21# |

0.81 |

0.813 |

0.80 |

|

22# |

0.71 |

0.711 |

0.70 |

|

Galvanized iron wire is available from 8# to 35# |

|||

Wire Diameter: 0.5mm–5.2mm.

Zinc Coating:

Hot-dip galvanized: 40–60g/m², 70–90g/m², 240–280g/m²

Electro-galvanized: 12–20g/m²

Tensile Strength: 350–500 N/mm²

Elongation: 15%–30%

Coil Weight: 25–800 kg. Also available in large coils (also known as loose coils), with weights ranging from approximately 100 kg to 1000 kg per coil.

Packaging: Mainly available in coiled wire or spooled wire.

Coiled wire: Plastic inside with woven outer packaging, or plastic inside with jute outer wrapping.

Spooled wire: Plastic-wrapped and packed in cartons.

Applications: Primarily used for weaving various types of metal mesh, construction binding wire, electric wires and cables, medical devices, brush manufacturing, clothes hangers, steel wire ropes, handicrafts, and other industries.