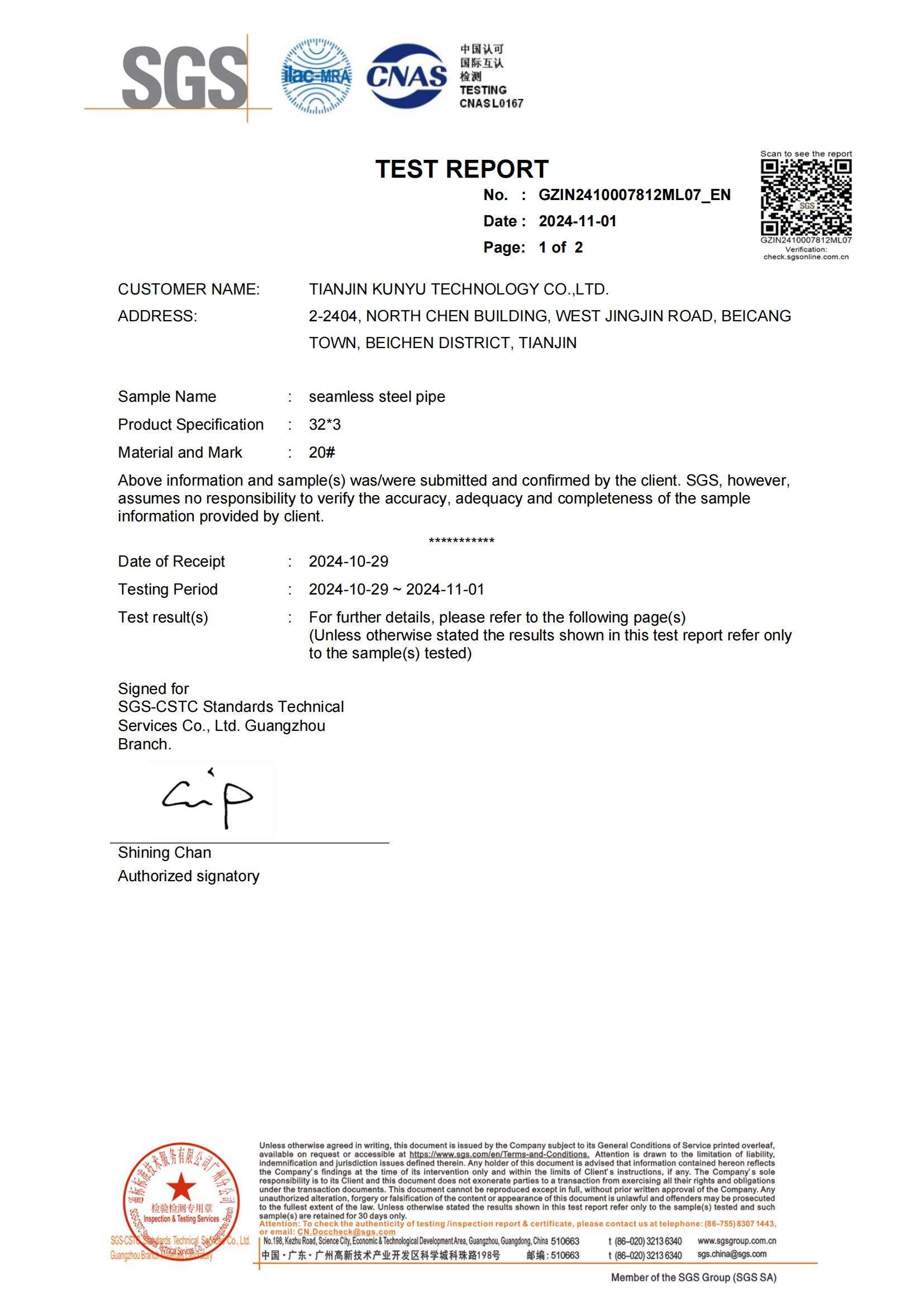

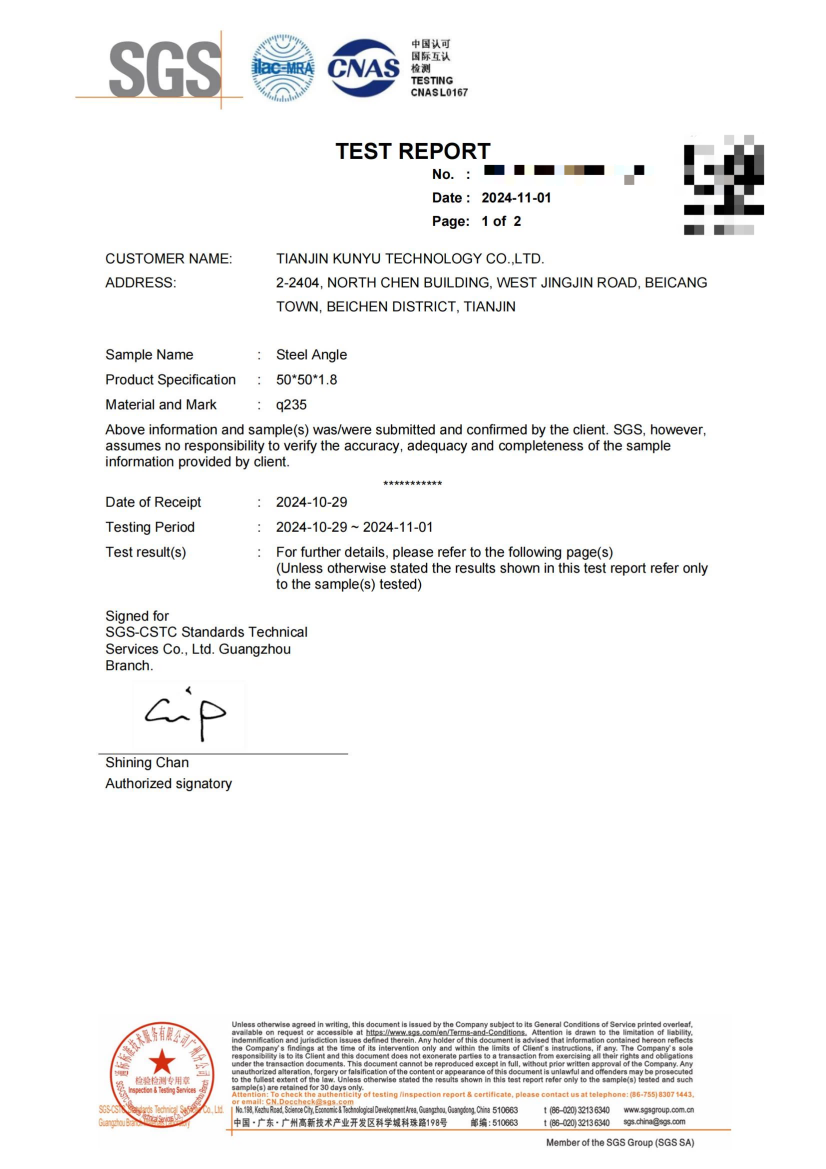

Carbon steel round pipe hot rollde black tube ASTM AISI

Black steel seamless pipe is a type of elongated steel material. Steel pipes have a hollow cross-section and are widely used as pipelines for transporting fluids, such as oil, natural gas, coal gas, water, and certain solid materials.

The production of circular parts using seamless carbon steel pipes can improve material utilization, simplify manufacturing processes, save materials and processing time, such as rolling bearing rings, jack sleeves, etc. Currently, steel pipes are widely used for manufacturing.

Description

| Parameter | Unit | Value / Range | Notes |

|---|---|---|---|

| Outer Diameter (OD) | mm | 10 – 610 | Typical industrial seamless pipe size range |

| Wall Thickness | mm | 1 – 40 | Depends on pressure and material grade |

| Length | m | 5.8 / 6 / 12 | Can be cut to customer requirements |

| Material | — | 20#, 20G, 45#, Q345B, 16Mn | Common carbon steel grades |

| Yield Strength | MPa | 235 – 470 | Depends on material grade |

| Tensile Strength | MPa | 375 – 630 | Varies with steel grade |

| Working Pressure | MPa | ≤25 | High-pressure pipes require thicker walls |

| Standard | — | GB/T 8162, GB/T 8163, ASTM A106, EN 10216 | Can be selected based on customer requirements |

Common Grade

| Base Material (China GB) | Equivalent US Standards (ASTM / API) | Equivalent European Standards (EN / DIN) | Other International Standards | Key Characteristics | Typical Applications |

|---|---|---|---|---|---|

| 20# | ASTM A106 Gr.B ASTM A53 Gr.B API 5L Gr.B |

EN 10216-2 P235GH EN 10216-2 P235TR1 EN 10208 L245 |

ISO 3183 L245 JIS G4051 S20C |

Balanced strength & ductility Excellent weldability Most widely used grade |

Fluid pipelines Oil & gas Water supply General industrial use |

| 20G | ASTM A106 Gr.C | EN 10216-2 P265GH DIN 17175 St45 |

— | Higher strength than 20# Good performance at elevated temperatures |

High-temp & high-pressure pipelines Boilers Power & energy |

| 45# | ASTM A105 | EN 10297-1 E470 | JIS S45C | High strength Good wear resistance |

Mechanical manufacturing Load-bearing components Machinery parts |

| Q345B | ASTM A572 Gr.50 | EN 10210 S355 | JIS SM490 | High strength Good toughness Excellent load capacity |

Steel structures Engineering structures Bridges |

| 16Mn | API 5L X42 / X52 | EN 10208 L290 / L360 | ISO 3183 L290 | High yield strength Suitable for high-pressure service |

Oil & gas transmission pipelines Mainline & heavy-duty pipelines |

Seamless Steel Pipe vs Welded Steel Pipe

| Dimension | Seamless Steel Pipe | Welded Steel Pipe |

|---|---|---|

| Production Process | Formed from solid steel billet by extrusion, piercing, drawing or rolling; no weld seam | Rolled from steel plate or strip and welded (ERW, spiral, longitudinal) |

| Mechanical Properties | Uniform wall thickness, high strength, high pressure & temperature resistance, strong burst resistance | Weld seam may have stress concentration, slightly lower strength, suitable for low-pressure and general structural use |

| Application Scenarios | High-pressure boilers, oil & gas pipelines, mechanical manufacturing, shipbuilding, boilers | Water pipelines, gas pipelines, construction structural pipes, general industrial pipelines |

| Price | Relatively high | Relatively low; welded pipe has lower manufacturing cost |

Competitive Advantage

The core advantages of carbon steel round pipes lie in their high cost-performance ratio—delivering exceptional strength, ease of processing, and widespread availability at a relatively low cost, making them an indispensable material across diverse industries.

-

High Strength and Excellent Mechanical Properties

Carbon steel round pipes offer high tensile, compressive, and bending strength, enabling them to withstand heavy loads, high pressure, and strong impacts. This makes them ideal for applications requiring structural integrity and durability, such as building frameworks, bridges, and heavy machinery.

-

Cost-Effectiveness and Affordability

Due to the abundance of raw materials (iron and carbon) and mature, large-scale production processes, carbon steel pipes are significantly more economical compared to alloy pipes like stainless steel or aluminum. They provide exceptional value for budget-sensitive or large-scale projects, reducing overall costs without compromising performance.

-

Superior Processability and Weldability

Carbon steel is easy to cut, bend, drill, and thread. It also exhibits excellent weldability, allowing secure and reliable connections through various welding methods (e.g., arc welding, gas shielded welding). This flexibility simplifies customization and assembly, enhancing project efficiency.

-

Wide Availability and Full Recyclability

Carbon steel round pipes are standardized industrial products available in extensive specifications (from thin to thick walls, small to large diameters) and are readily sourced globally. Moreover, carbon steel is 100% recyclable, supporting environmental sustainability and circular economy practices.