Aluminum square bar Aluminum rod

An aluminum square bar is a long, bar-shaped aluminum material, typically with a circular, square, or hexagonal cross-section. It can be manufactured through processes such as extrusion, drawing, or casting.

Aluminum square bar offer high strength and hardness, making them suitable for use in various mechanical parts, construction materials, and electronic products. Thanks to their excellent electrical and thermal conductivity, they are also widely used in producing electrical wires, heat sinks, and electronic cooling components.

Description

Products name |

Aluminum square bar |

Model Number |

7075 6061 5083 3003 2024 all series |

Application |

aircraft mobile phones ships cars |

Surface Treatment |

Polished |

Shape |

Square |

Technique |

EXTRUDED |

Grade |

7000 Series |

Hardness |

customized |

Thickness |

customized |

Alloy Or Not |

Is Alloy |

Yield (≥ MPa) |

275 |

Temper |

T3 - T8 |

Ultimate Strength (≥ MPa) |

310 |

Tolerance |

±3% |

Processing Service |

Bending, Decoiling, Welding, Punching, Cutting |

Product Business Terms

|

Minimum Order Quantity: |

1 ton |

|

Price: |

1500-2000/ton |

|

Processing Service |

Bending, Decoiling, Welding, Punching, Cutting |

|

Delivery Time: |

15-21days |

Product Presentation

An aluminum square bar is a long, bar-shaped aluminum material, typically with a circular, square, or hexagonal cross-section. It can be manufactured through processes such as extrusion, drawing, or casting.

Aluminum square bar offer high strength and hardness, making them suitable for use in various mechanical parts, construction materials, and electronic products. Thanks to their excellent electrical and thermal conductivity, they are also widely used in producing electrical wires, heat sinks, and electronic cooling components.

The casting process of aluminum rods

(1) Batching:

Based on the specific alloy grade to be produced, the amounts of various alloying elements are calculated, and raw materials are proportionally blended accordingly.

(2) Melting:

The batched raw materials are charged into the melting furnace according to process requirements. Through degassing and flux refining, impurities and gases are effectively removed from the molten metal.

(3) Casting:

The molten aluminum is cast under specific casting conditions into round billets of various specifications using a vertical direct-chill (DC) casting system.

Note: The aluminum price fluctuates widely. Please communicate with customer service for a quotation before placing an order.

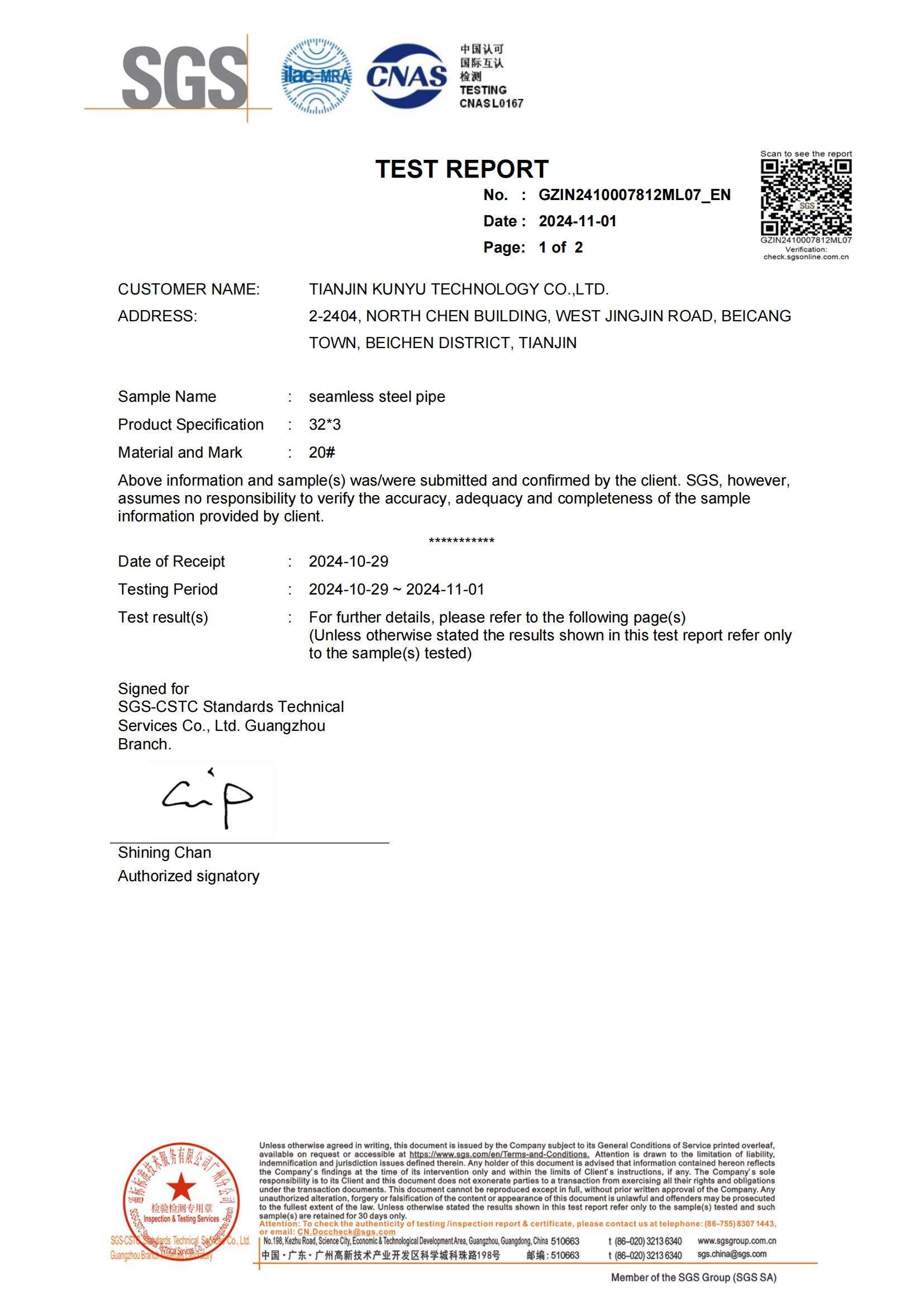

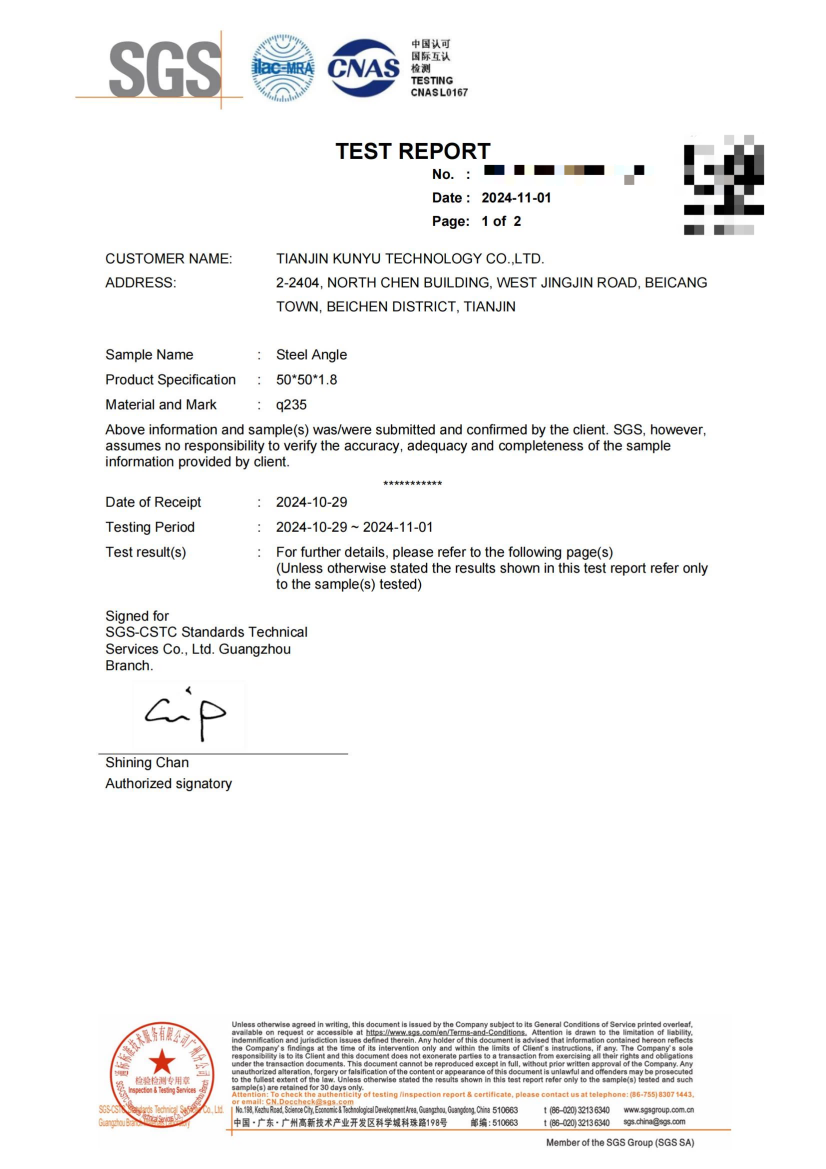

Services

OEM&ODE

Processing Service:Bending, Decoiling, Welding, Punching, Cutting

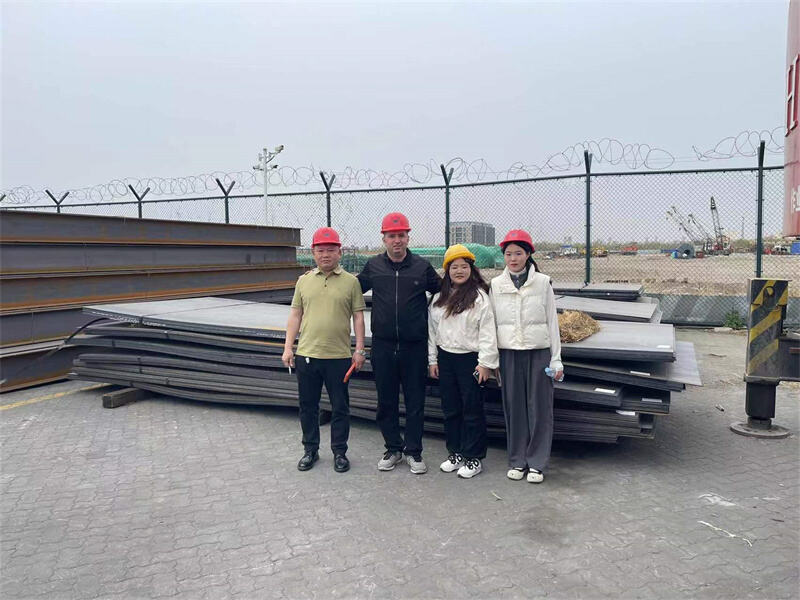

Factory inspection at any time

Request Free Sample