Hot rolled carbon steel coil

We supply a wide range of grades and specifications, with thickness from 0.17mm to over 20mm, customizable widths, and optional processing services such as slitting and cut-to-length.

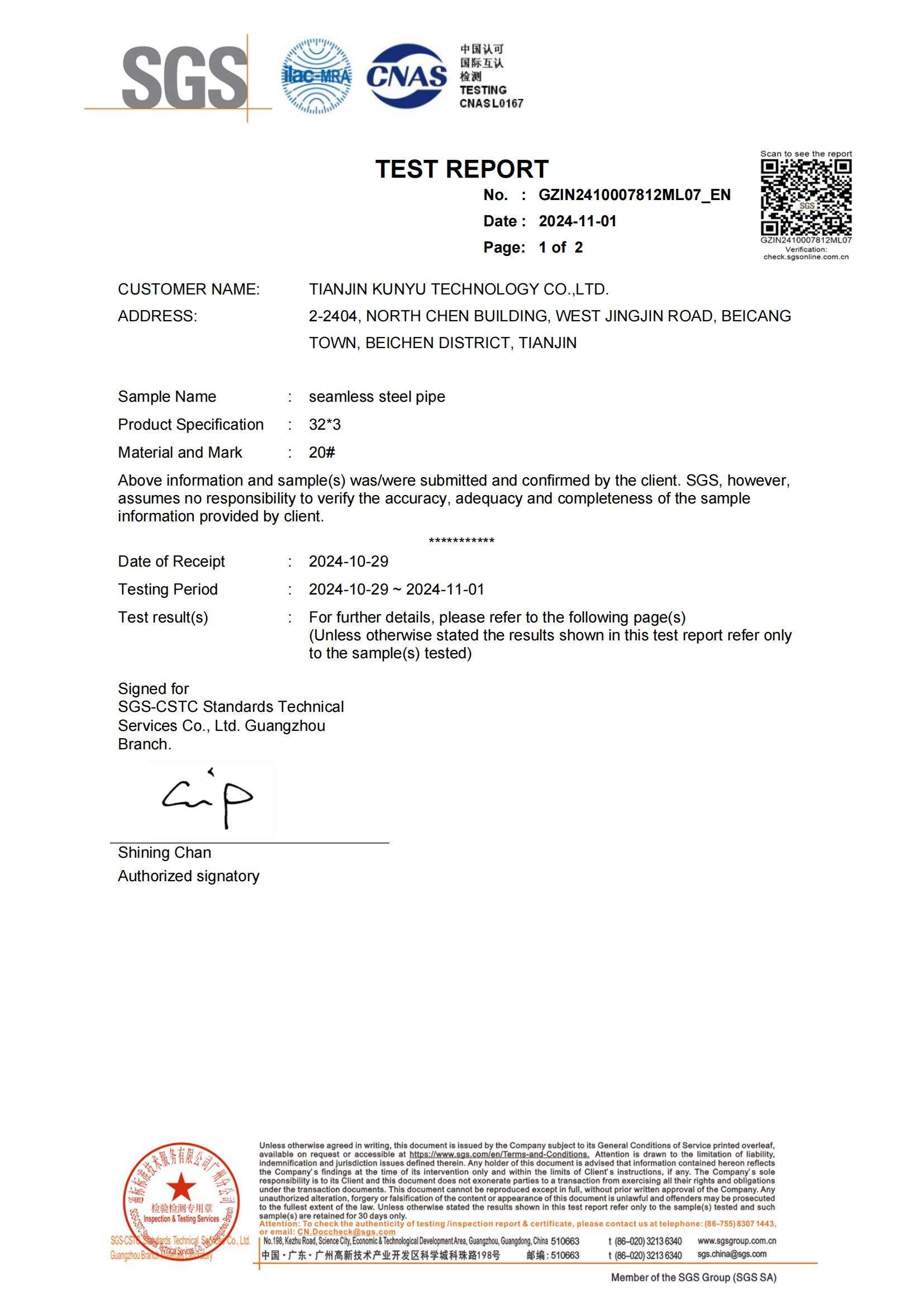

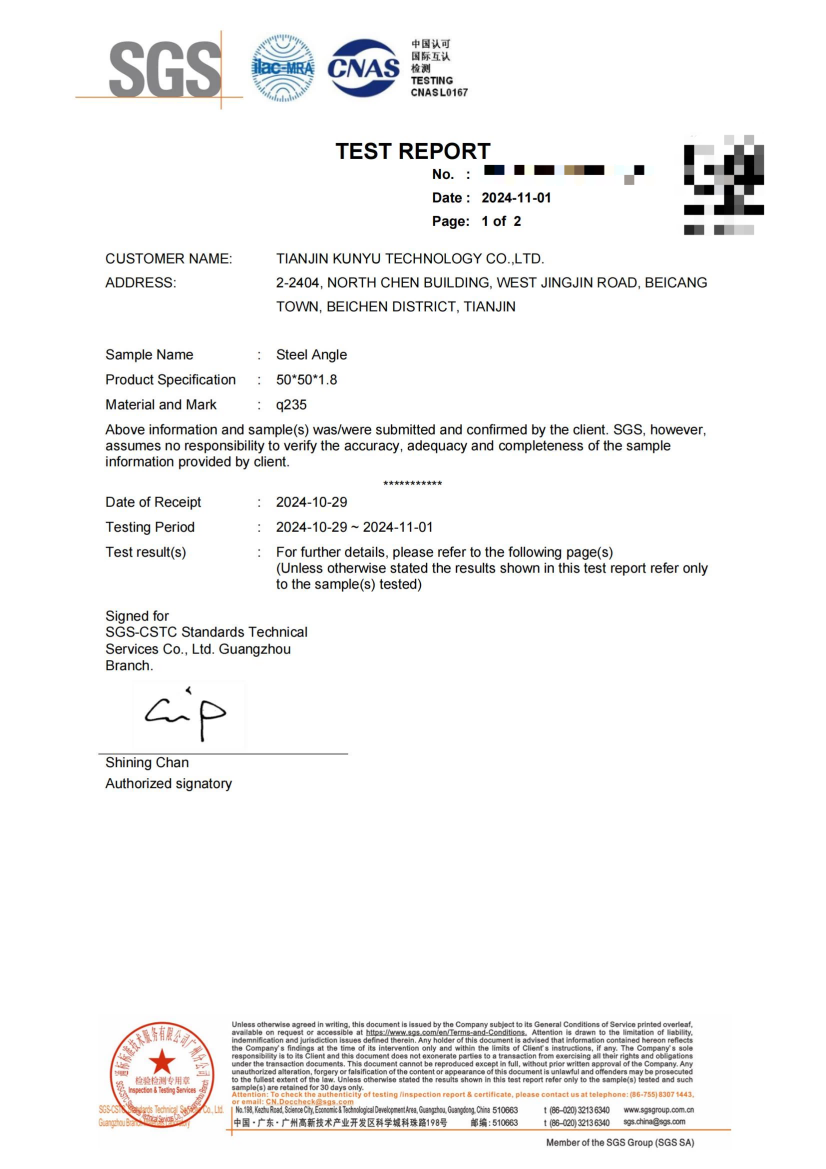

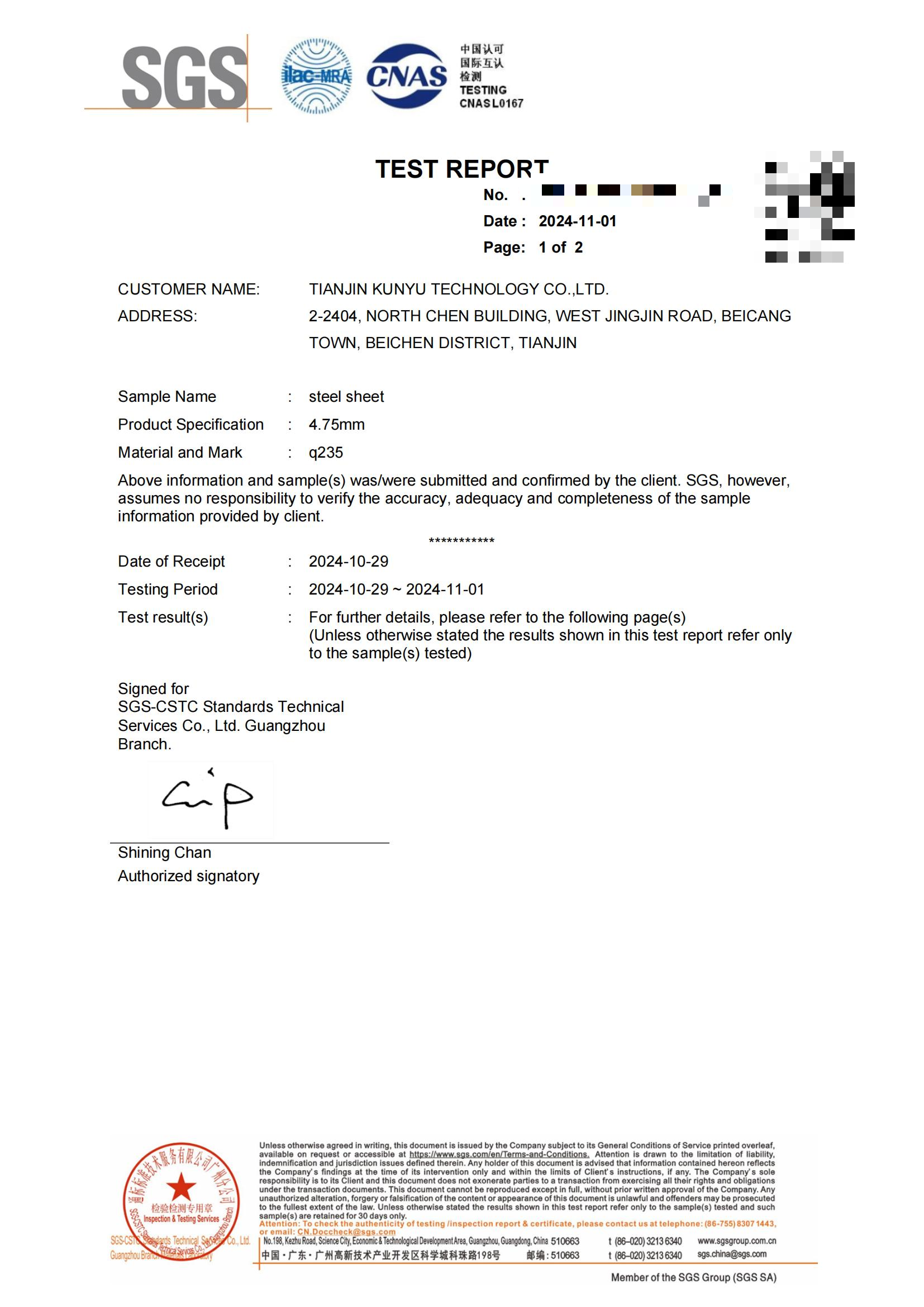

With strict quality control throughout smelting, rolling, and inspection, all products can be provided with Mill Test Certificates (EN 10204 3.1).

Tell us your required grade, thickness, and quantity, and our technical team will quickly recommend the most suitable solution for your project.

Description

Grade correspondence table

Production & Quality Control

Carbon Steel Coil Production & Quality Control

From raw material selection to final delivery, KUNYU implements a strict and standardized production process to ensure stable quality of carbon steel coils. Steelmaking, rolling, controlled cooling, and coiling are carried out under carefully monitored conditions to maintain consistent chemical composition, mechanical performance, and dimensional accuracy.

Each batch undergoes systematic inspection, including chemical analysis, mechanical testing, and surface quality checks. Mill Test Certificates (EN 10204 3.1) are available upon request, ensuring full traceability and compliance with international standards.

Production Flow

Steelmaking → Hot Rolling → Controlled Cooling → Coiling → Inspection → Packing

Competitive Advantage

-

Diverse Specifications

Our carbon steel coils are available in a wide range of thicknesses, from as thin as 0.17mm to over 20mm, with widths also customizable according to requirements. This allows you to select specifications based on your project needs, reducing constraints related to material adaptation and simplifying the procurement process by eliminating the need to source from multiple suppliers, thereby lowering management costs.

-

Excellent Processability

The flexibility in processing carbon steel coils is a standout feature. We also offer one-stop processing services, providing you with components in the desired shapes and sizes. This minimizes the need for secondary processing, effectively shortens production cycles, and reduces investment in equipment as well as energy consumption.

-

Wide Range of Applications

Thanks to their versatile properties and workability, carbon steel coils are widely used in various fields such as automotive manufacturing, hardware products, mechanical components, and the construction industry.

-

Consistent Quality

Through precisely controlled production processes—including strict oversight of smelting, rolling, and cooling techniques—we ensure that key indicators such as chemical composition, mechanical properties (e.g., strength and hardness), and surface quality consistently meet standard requirements.