Galvanized steel strip

We use high quality hot rolled coil as raw materials for producing cold rolled after pickling,continuous rolling, degreasing, annealing, skin pass, slitting etc. Good surface quality and high density can be widely used for food-grade tin plate, galvanized plate,house-hold appliance, building materials,electronics, automobile manufacture,petroleum chemical industry and architecture fields.

Description

Product Name |

Galvanized steel strip |

Width |

600mm-1500mm,according to customer's requirement |

Thickness |

0.12-6.00mm,or customer's requirement |

Length |

6-12m or According To Customer's Demends |

Surface Structure |

Normal spangle coating(NS),minimized spangle coating(MS),spangle-free(FS) |

Advantages |

1.low foundation cost 2.easy construction 3.time and labor saving |

Type of Coating |

Hot Dipped Galvanized Steel(HDGI)/Electro-Galvanised Steel(EGI) |

Surface Treatment |

1. Galvanized |

Product Application |

1. Fence, greenhouse, door pipe,greenhouse |

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

Product Business Terms

|

Minimum Order Quantity: |

1 ton |

|

Price: |

430-490/ton |

|

Payment terms |

30%T/T Advance + 70% Balance |

|

Packing |

Standard Sea-worthy Packing |

|

Delivery Time: |

15-21days |

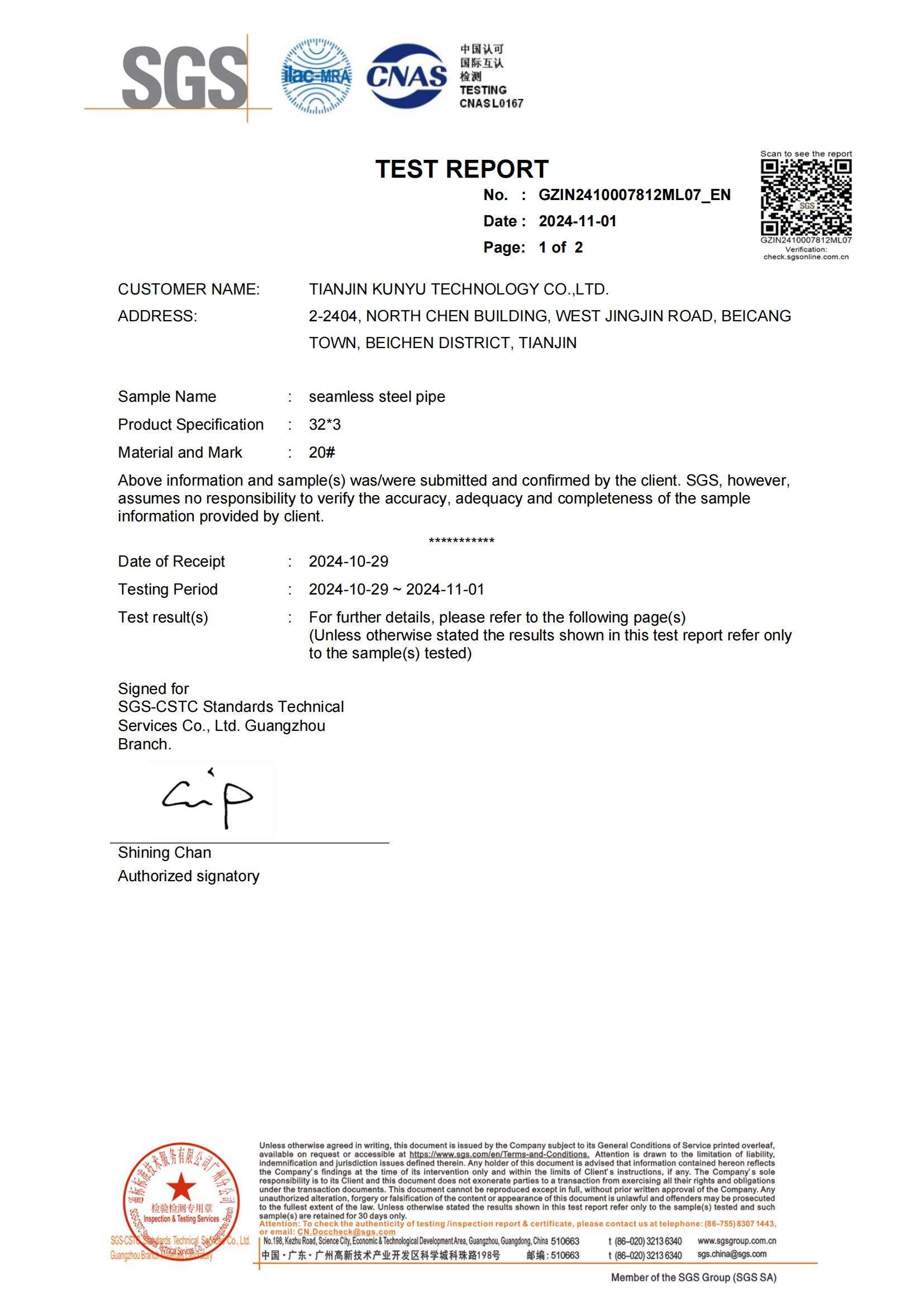

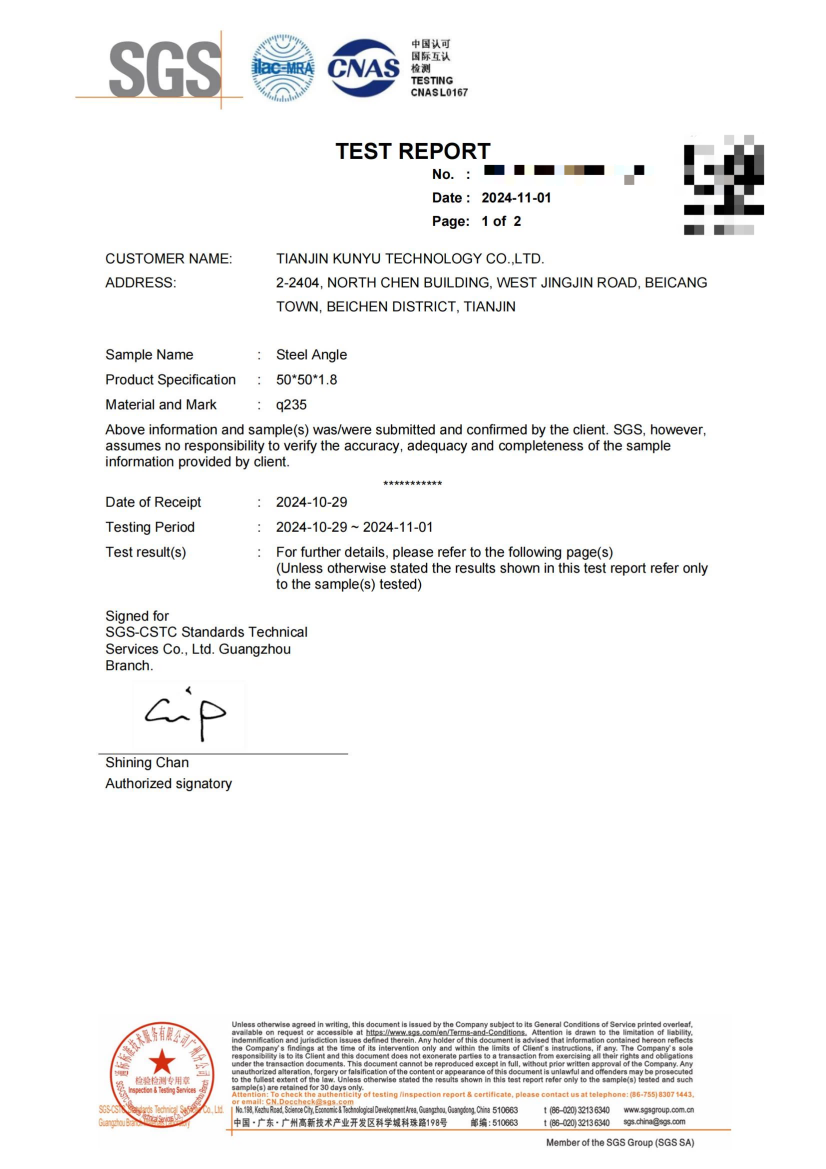

Product Presentation

Galvanized strip refers to a steel strip that undergoes an electroplating process, coating its surface with a layer of zinc to enhance its corrosion resistance and service life. This type of galvanized strip is commonly used to manufacture various metal conduits, distribution boxes, cable trays, and other electrical equipment, as well as tools and components for agricultural and construction applications.

Specifications

| Grade | SGCC,SGCD,SGHC,DX51D-DX54D |

| Thickness | 0.1mm-5.0mm |

| Width | 25mm-600mm for strip,600mm-1500mm for coil |

| Zinc Coating | Z30g-Z275g |

| Coil Weight | 3-7 tons |

| Inner Diameter | 508mm,610mm |

Competitive Advantage

1. Corrosion Resistance: The zinc coating effectively isolates the steel substrate from corrosive elements such as oxygen and moisture. Even if the surface is slightly scratched, zinc will corrode preferentially, thereby protecting the underlying steel. Its corrosion resistance is typically more than ten times higher than that of ordinary carbon steel coils, making it especially suitable for harsh environments such as humid or coastal areas with salt spray and industrial atmospheres.

2.Workability and Aesthetics: Galvanized steel strip generally offer excellent formability and weldability, facilitating subsequent processing and manufacturing. At the same time, the surface is smooth and uniform with a silvery metallic luster and an attractive appearance, allowing it to be used directly in applications where aesthetics matter—such as roofing, wall panels, and home appliance exteriors—without the need for additional painting.

3.Cost Efficiency and Environmental Benefits: Although the initial procurement cost of galvanized steel strip is higher than that of carbon steel, their long service life and minimal maintenance requirements (no frequent repainting for rust prevention) can lead to lower overall lifecycle costs. From an environmental perspective, zinc is recyclable, and its use reduces VOC (Volatile Organic Compounds) emissions generated from repeated maintenance painting.

Applications

-

Construction

Used in building materials such as light steel frames, guardrails, and roofing panels.

-

Automotive

Applied in auto parts including car bodies, fuel tanks, and fenders.

-

Home Appliances

Employed for external housings of appliances like air conditioners and washing machines

-

Agriculture & Commercial

Utilized in grain storage and transportation equipment, as well as cold storage processing systems.

-

Power & Communications

Used in structures such as power transmission towers and communication towers.