Galvanized seamless pipe square tube

Hot-dip galvanized squarel pipe is a type of corrosion-resistant steel pipe formed by immersing steel pipes in molten zinc to create a zinc coating, featuring excellent corrosion resistance and mechanical strength. Its core advantage lies in the formation of an alloy layer between the zinc coating and the steel pipe substrate, significantly extending its service life. It is widely used in construction, energy, transportation, and other fields.

Description

Product Name |

Hot Dipped Galvanized Square Pipe |

Surface Finish |

Pre-galvanized, Hot dipped galvanized, Electro galvanized, Black, Painted, Threaded, Engraved, Socket. |

Thickness |

Square pipe10*10mm-500*500mmas customer request. |

Technique |

Pre galvanized:5μm-25μmHot dipped galvanized:35μm-200μm |

Length |

12m or as required |

Delivery time |

15-20 days after the deposit or LC. |

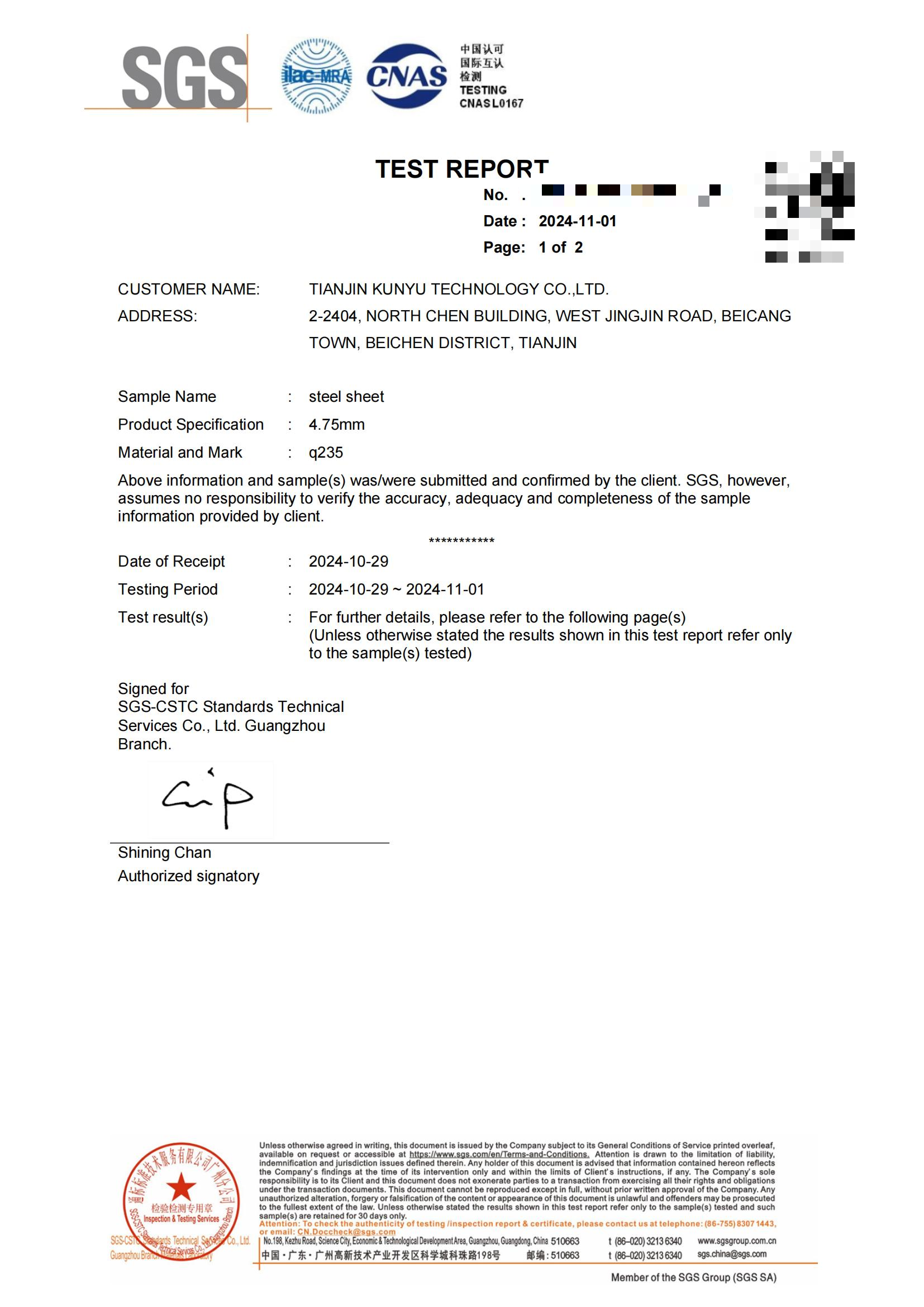

Steel Grade |

Q235, Q345, S235JR, S275JR, STK400, STK500, S355JR, GR.B-D |

Product Business Terms

|

Price: |

550-800/ton |

|

Packaging Details: |

Standard Sea-worthy Packing |

|

Delivery Time: |

15-21 days |

|

Minimum order quantity |

1 ton |

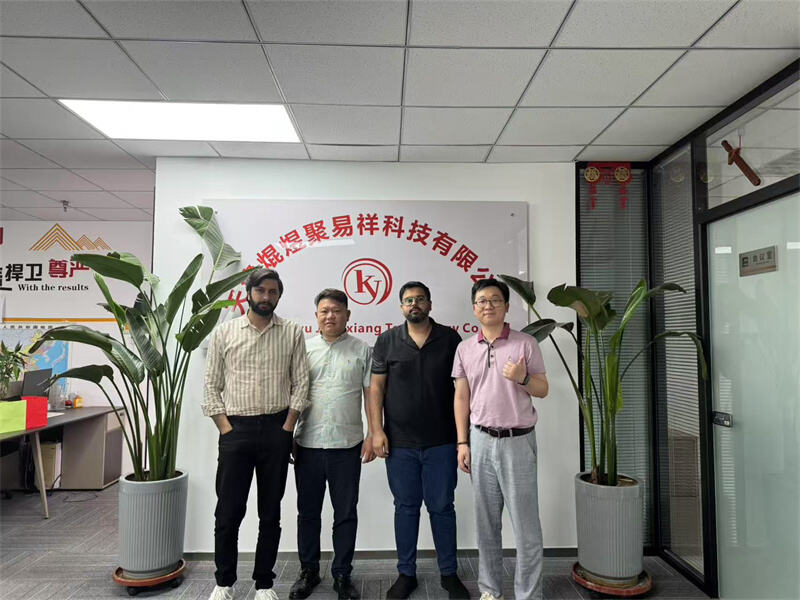

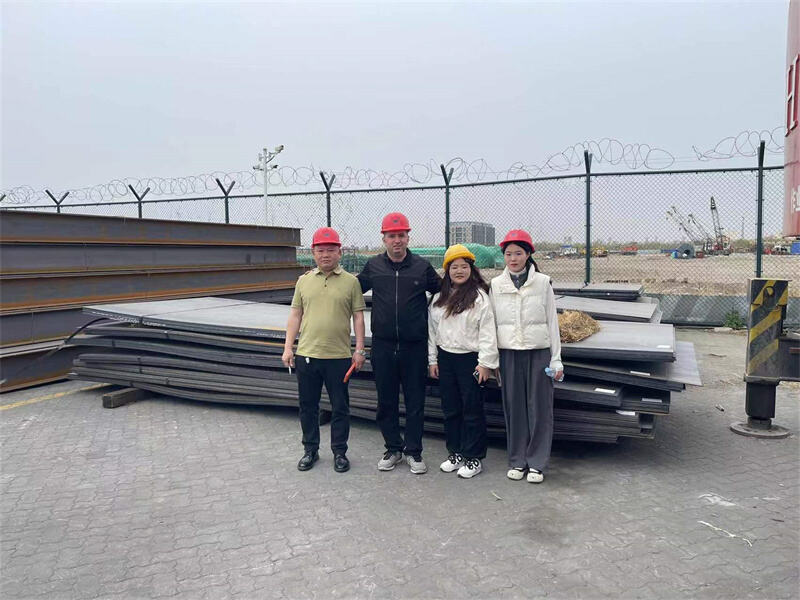

Product Presentation

Hot-dip galvanized squarel pipe is a type of corrosion-resistant steel pipe formed by immersing steel pipes in molten zinc to create a zinc coating, featuring excellent corrosion resistance and mechanical strength. Its core advantage lies in the formation of an alloy layer between the zinc coating and the steel pipe substrate, significantly extending its service life. It is widely used in construction, energy, transportation, and other fields.

Applications

Metal Frames and Structures:

Such as equipment guards, small display stands, storage racks, and furniture frames (e.g., chairs, tables, bed bases).

Architectural Decoration and Fencing:

Including decorative frames for doors and windows, curtain wall mullions, stair handrails, as well as outdoor fences and railings.

Venue Construction:

For example, large stadiums and arenas, platform shelters, carports, and roof and grid structures for sunrooms.

Mechanical Equipment:

Such as frames and supports for automation equipment and production lines.

Competitive Advantage

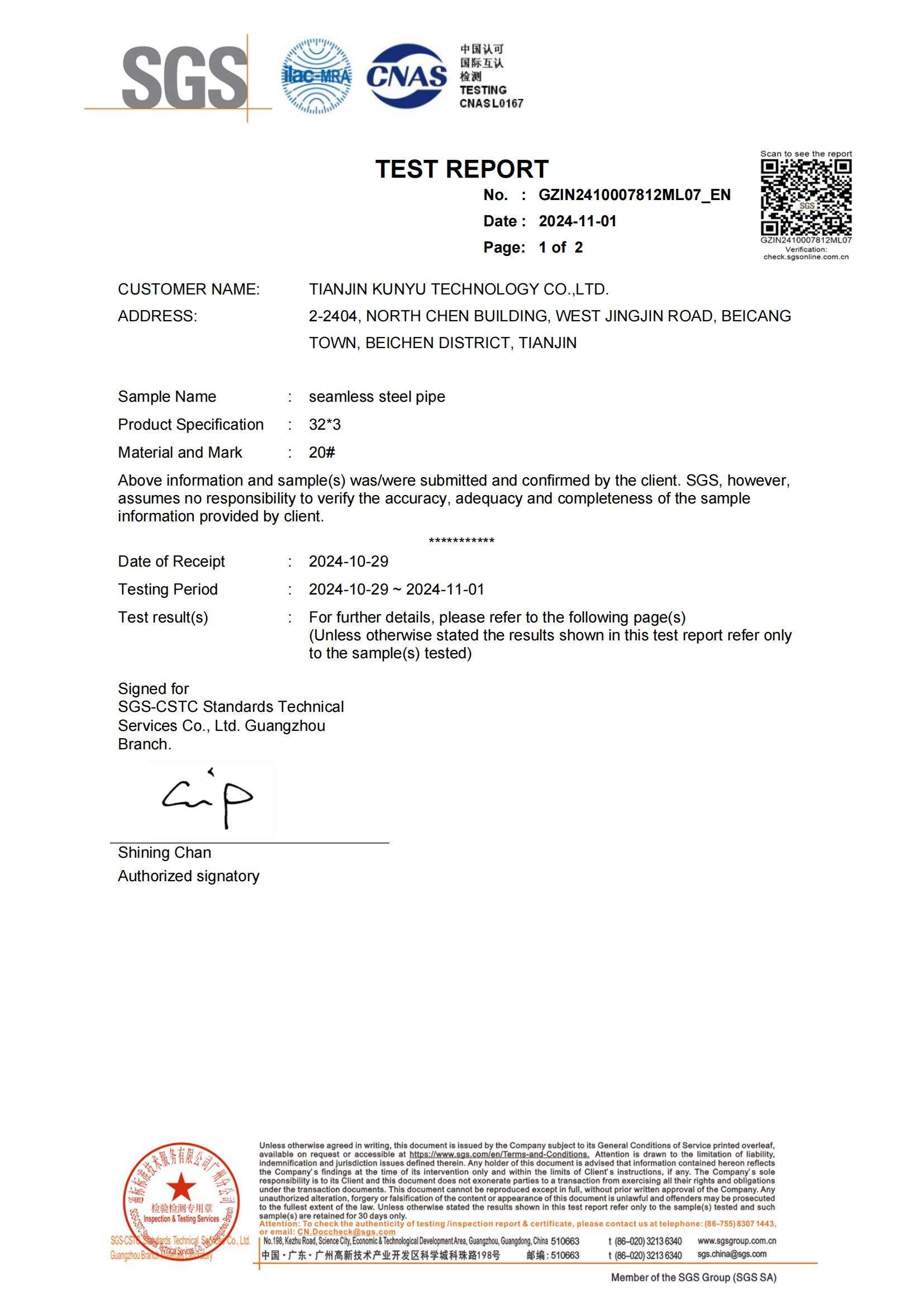

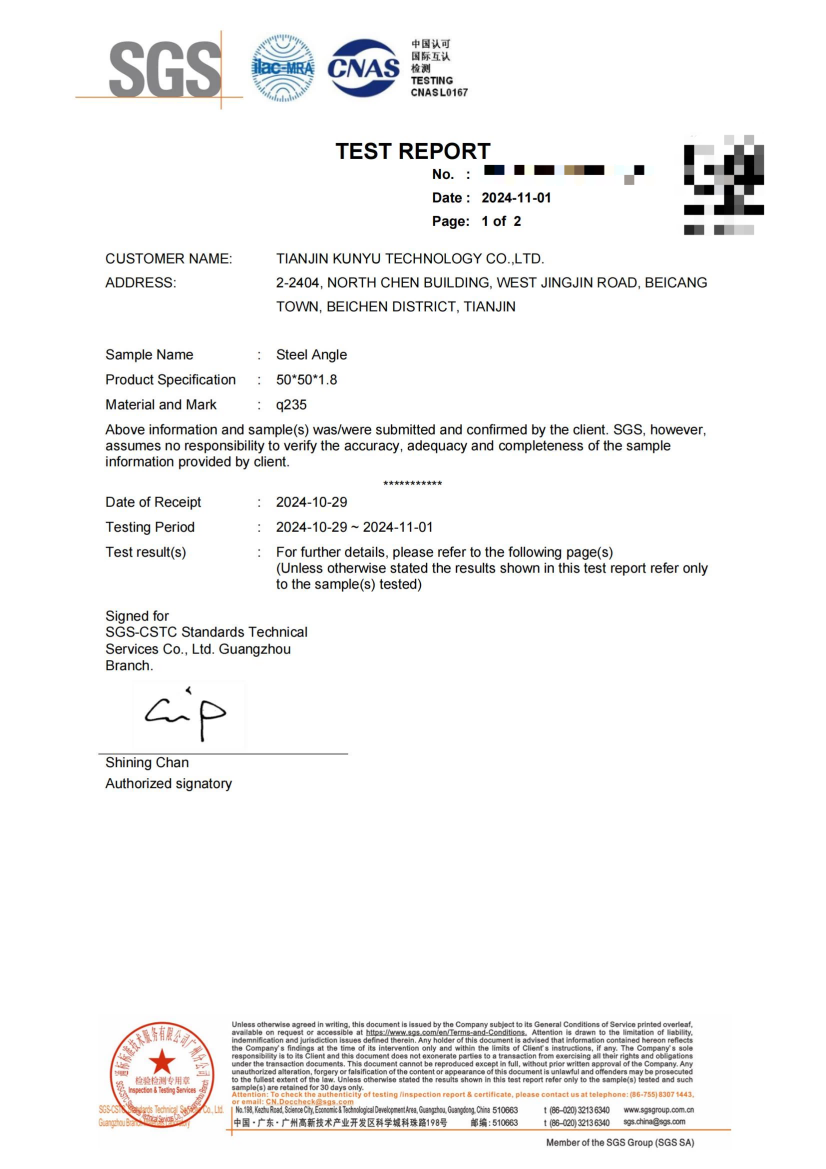

Excellent Corrosion Resistance: The zinc layer not only isolates the steel substrate from contact with corrosive media but also acts as a "sacrificial anode," meaning it corrodes preferentially in the event of minor surface damage, thereby continuously protecting the inner steel pipe. Its service life is typically several times longer than that of ordinary steel pipes.

Exceptional Strength and Pressure-Bearing Capacity: Seamless steel pipes have no welds, which gives them superior structural homogeneity, pressure-bearing capacity, and resistance to deformation compared to welded steel pipes. This makes them particularly suitable for high-pressure, high-strength, or critical load-bearing applications.

Long Service Life: Combining the above two advantages, galvanized seamless steel pipes provide long-lasting and reliable performance in various harsh environments, reducing the frequency of replacement and maintenance and ultimately lowering the total lifecycle cost.

Excellent Sealing Performance: The absence of welds significantly reduces the risk of leakage when transporting gases or liquids.