Description

Product Name |

Galvanized steel wire |

Grade |

SAE1006-1080,WA1010,Q195,SWRH32-37,SWRH42A-77A,SWRH42B-82B |

Standard |

GB standard,ASTM standard |

Wire Gauge |

5.5mm-34mm |

Tolerance |

+/-0.3mm |

Process |

Hot rolled |

Application |

Mechanical&manufacture,Steel structure,Shipbuilding,Bridging,Automobile chassis |

Lead Time |

A.7 days if this goods is stock goods.B.20 days if this goods will be produced after order |

Product Business Terms

|

Minimum Order Quantity: |

1 ton |

|

Price: |

380-500/ton |

|

Packing |

Seaworthy Standard Package |

|

Delivery Time: |

15-21days |

|

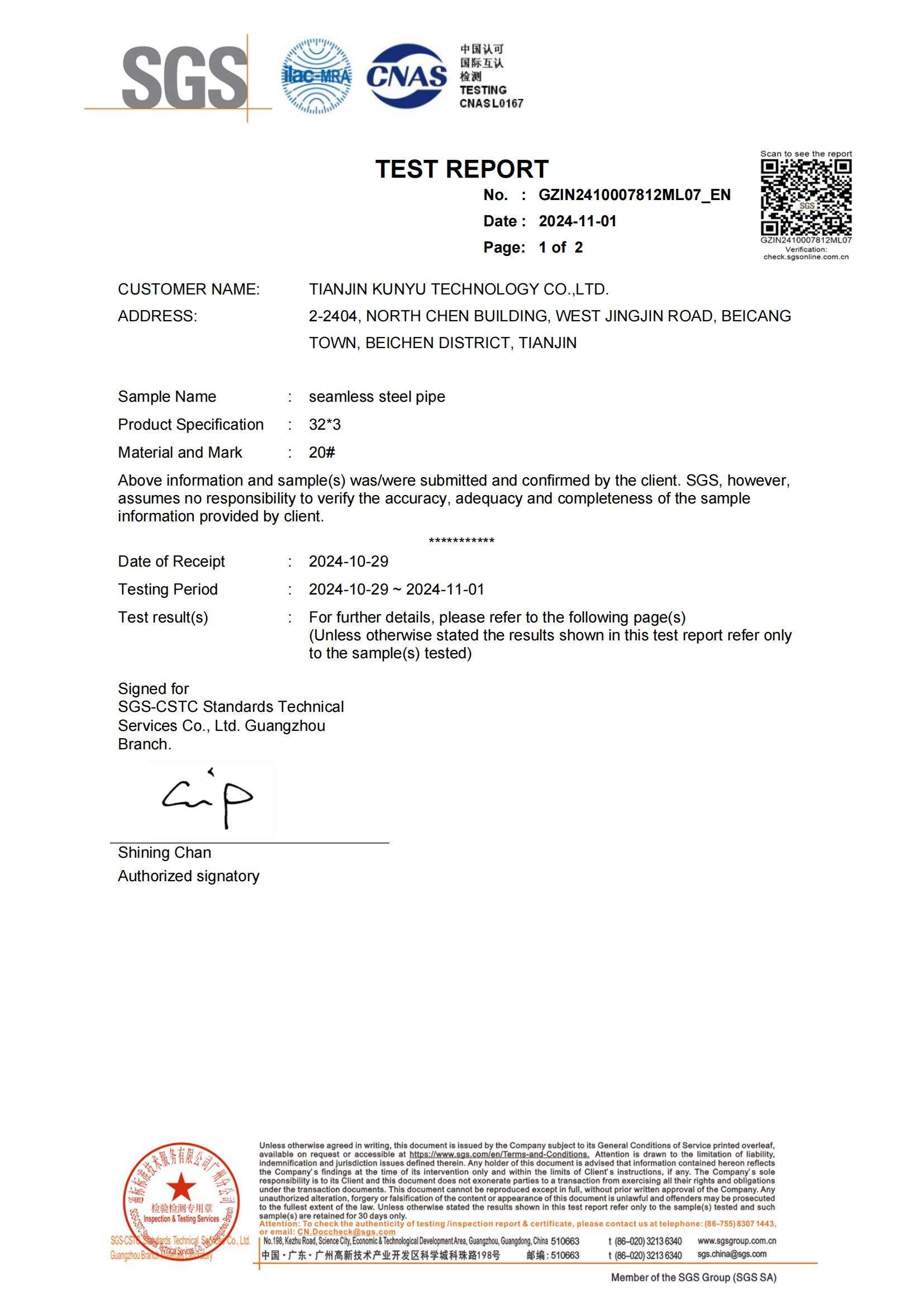

Certificate |

ISO9001,CE |

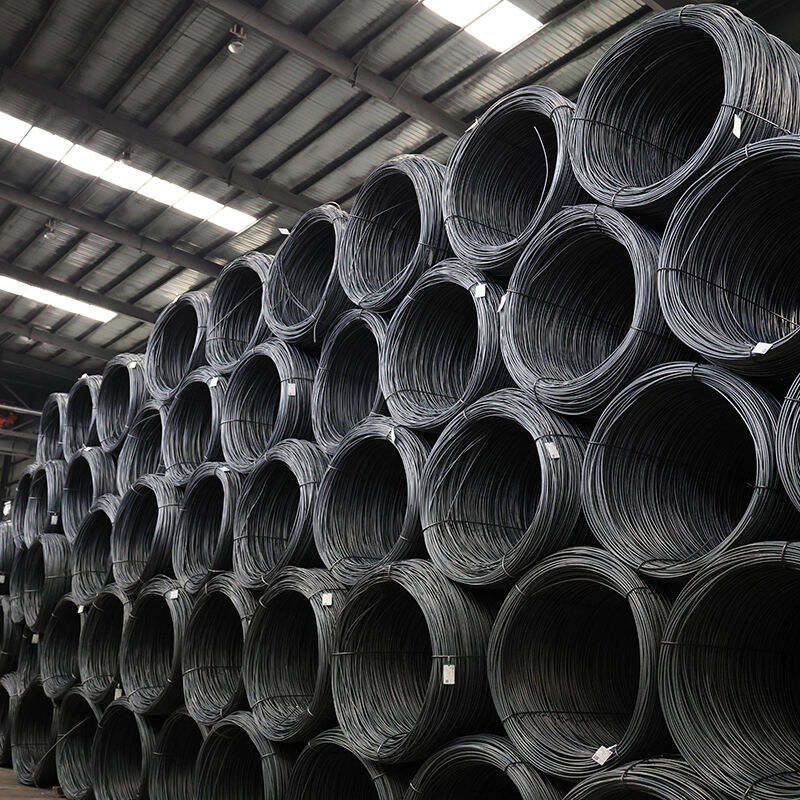

Product presentation

Carbon steel wire is manufactured by drawing high-quality high-carbon steel wire rods through a process that includes patenting treatment, pickling, copper plating or phosphating, and cold drawing. Each batch of our wire undergoes a series of strict tests, including visual inspections and mechanical performance testing, to ensure product quality for our customers. We maintain ample inventory and also support custom orders.

Product specification

|

Carbon Steel Wire |

|

|

Standard Specifications |

ASTM A228, ASTM A510, ASTM A1063, ASTM A313, JIS G3532, EN 10270-1, GB/T 3431, etc. |

|

Steel Grades |

SAE 1006, SAE 1008, SAE 1010, SAE 1045, SAE 1060, SAE 1070, SAE 1080, 65Mn, 70#, 72A, 82B, etc. |

|

Steel Type |

- Low Carbon Steel (C ≤ 0.25%) |

|

|

- Medium Carbon Steel (C = 0.25%-0.60%) |

|

|

- High Carbon Steel (C ≥ 0.60%) |

|

Surface Coating |

Uncoated (Black), Galvanized (Electro-Galvanized, Hot-Dip Galvanized), Phosphate Coated, etc. |

|

Production Process |

Cold Drawn, Hot Rolled, Annealed, Patented, Oil Tempered |

|

Wire Diameter Range |

0.10mm - 12.00mm or Customized |

|

Mechanical properties |

-Tensile Strength:350 - 2000 MPa |

|

|

-Yield Strength:200 - 1800 MPa |

|

|

-Elongation:≥ 10% |

|

|

-Hardness:45 - 65 HRC |

|

Applications |

Springs, wire mesh, fasteners, industrial cables, fencing, automotive components, reinforcing materials |

Applications

Carbon steel wire gains enhanced strength and hardness through cold working and heat treatment. It is widely used across light industry and construction sectors, with applications including nail production, reinforcing bar fabrication, welded skeletons, welded mesh, woven mesh for cement boats, hardware

products, and more.