Tubuli Saldati ex Ferro Inoxidiabili Tubi Rotundi

Tubus saldatus ex ferro producitur per flectendum et formandum laminas aut fascias ferreas, deinde saldando iuncturas inter se.

Comparatis tubis ex ferro sine sutura, tubi saldati offerunt processum productionis magis adfectivum et efficacius, resultans in pretio competitivo in foro. Quoad functionem, tubi saldati certe implent conditiones applicationum pressionis normalium, cum capacitate sustinendi pressionem circiter 10 MPa, eosque valde versatiles reddendo.

Descriptio

Nomen Producti |

tubus soldatus ex stadio inoxydabili |

Materies (DIN) |

201, 202, 301, 302, 303, 304, 304L, 309, 310, 310S, 316, 316L, 316Ti, 317L, 321, 347, 405, 409, 410, 420, 430, 436, 439, 444, 446, 904L, 2205 (duplex), 2507 (super duplex), 17-4PH, et aliae species speciales. |

Superficies |

Decapatus/Lucidus/Pulcher |

Diametros Externa |

6-610mm |

Crassitudo |

1.5-50mm |

Longitudo |

Customizatum |

Forma |

Rotundus |

Standardus |

ASTM DIN GB JIS EN AISI |

Gradus |

201/304/304L/321/316/316L/310S/904L/309S/316Ti/317L/2205/2507, etc. |

Technica |

Laminatus Frigore, Laminatus Calore vel Soldatus |

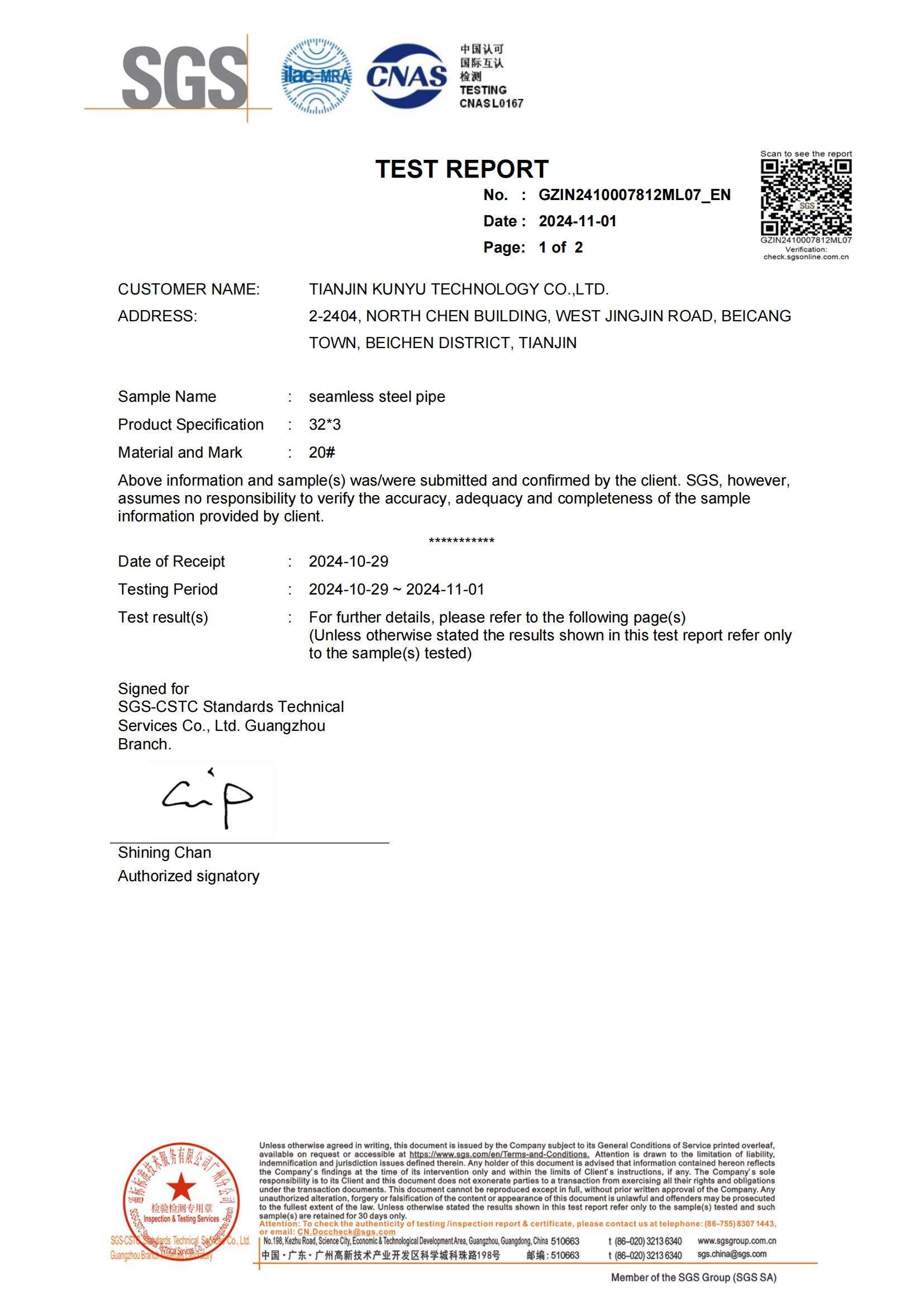

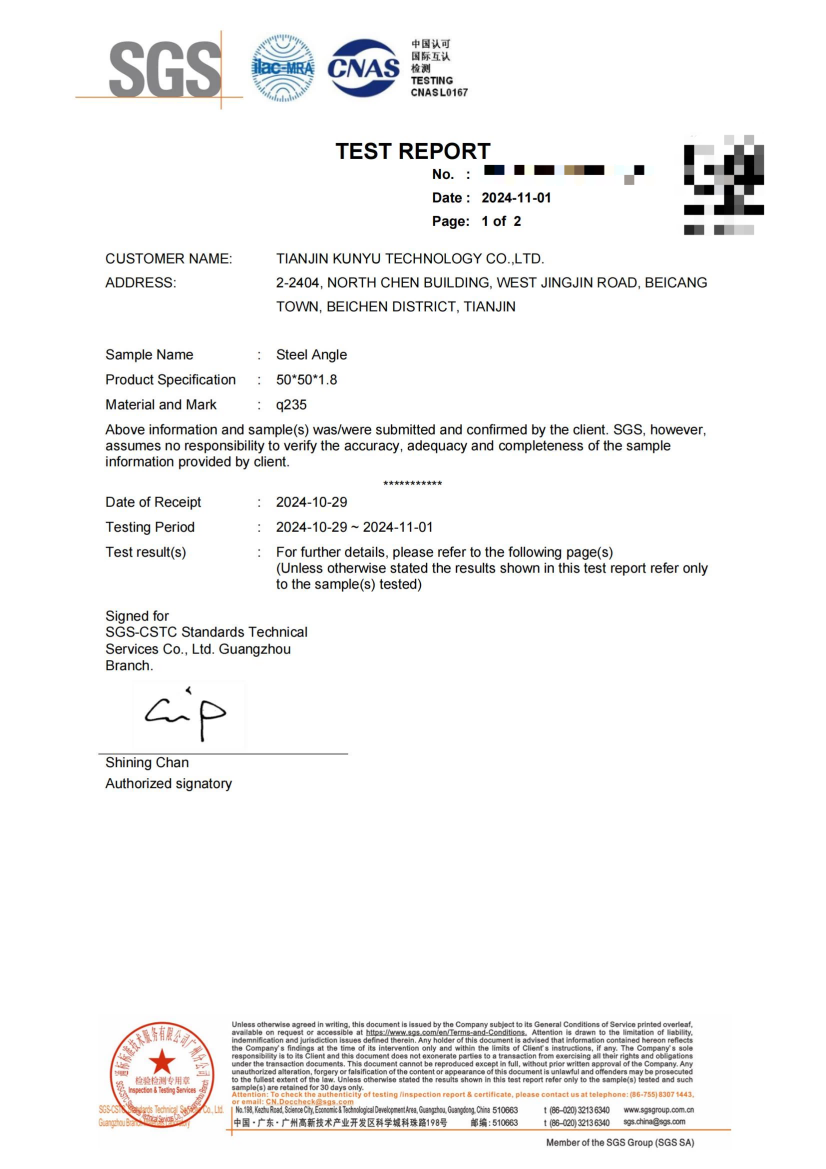

Certificatio |

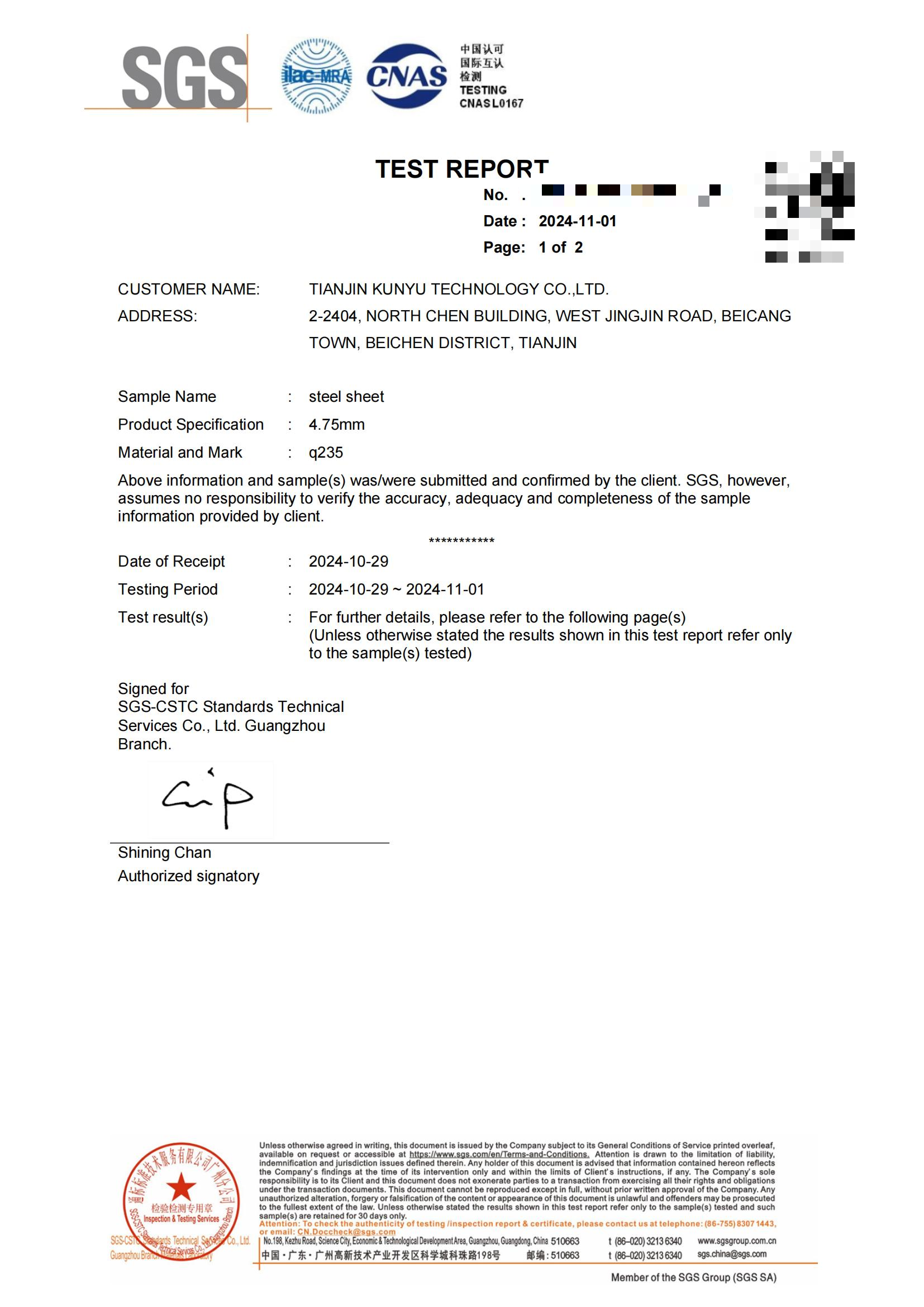

ISO9001, SGS, BV, ISO, CE |

Used " |

Machinaria Industria Aedificatoria, etc. |

Sarcina |

Export standardis plico vel secundum petitionem clientium |

Tempus Traditionis |

Solito 7-15 dies, vel ex negotiatione |

Pretium Terminos |

FOB, CRF, CIF, EXW omnes acceptabiles |

compos mentis chemici (%) | |||||||

Gradus ASTM |

C |

Si |

Mn |

S |

P |

Cr |

Ni |

201 |

≤0.15 |

≤0.75 |

5.50-7.50 |

≤0.030 |

≤0.060 |

16.00-18.00 |

3.50-5.50 |

304 |

≤0.07 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.035 |

17.00-19.00 |

8.00-11.00 |

304L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.035 |

18.00-20.00 |

8.00-12.00 |

309S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.035 |

22.00-24.00 |

12.00-15.00 |

310S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.035 |

24.00-26.00 |

19.00-22.00 |

316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.045 |

16.00-18.00 |

10.00-14.00 |

316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.035 |

16.00-18.00 |

12.00-15.00 |

Usus

Tubus sanitarius: ad industria processuum alimentorum, industriam potum, officina sacchari et cetera;

Tubus excambiatoris caloris: condensator, balneum, calefactor superior, evaporator et cetera;

Tubus industrialis: ad vehiculationem petroleum, vehiculationem gas, industriam petrochemicam, tractationem aquae sordidae, systema cloacarum, et cetera;

Tubus mechanicus: balustris, postes, parapetum, et cetera.